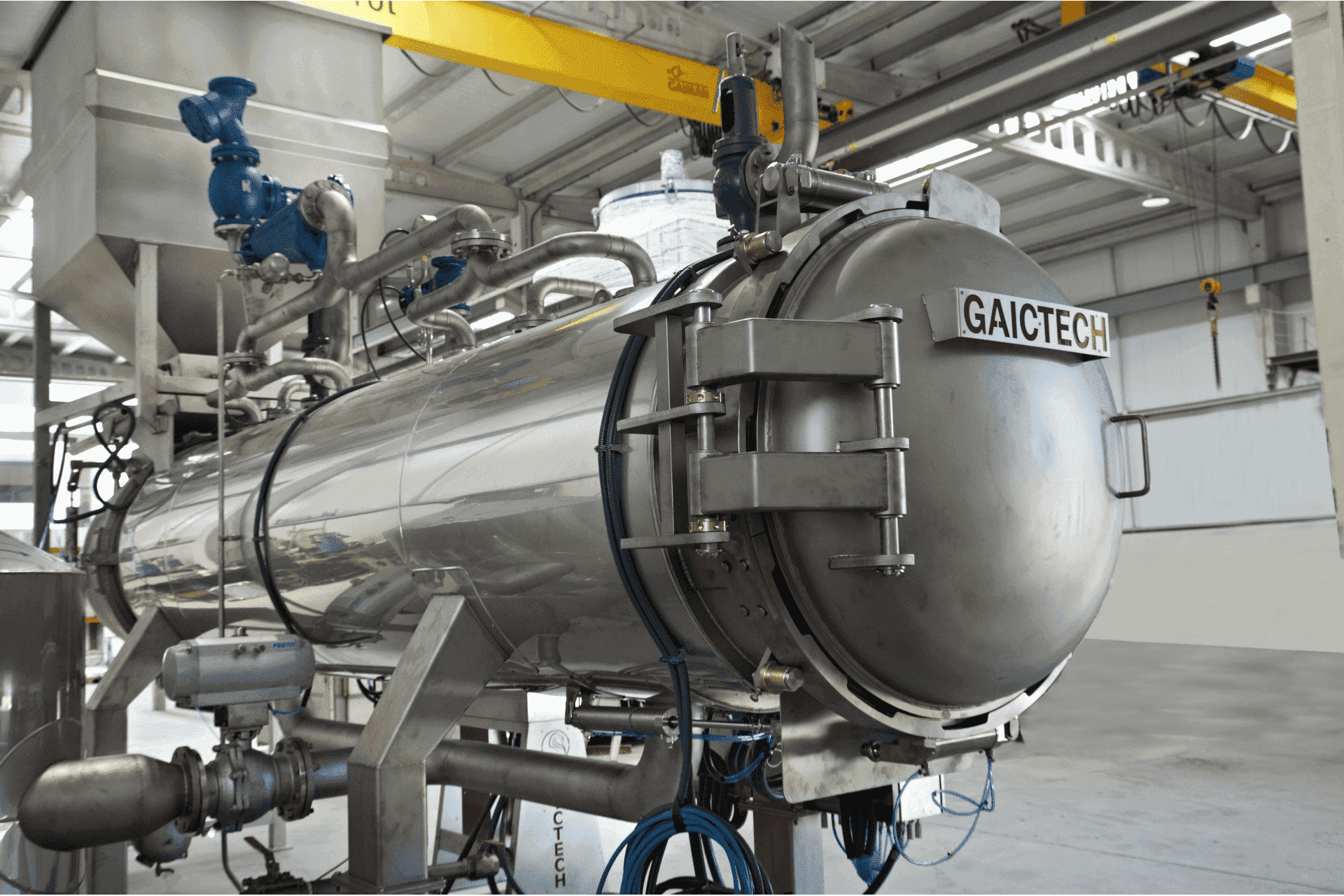

Mussel Cooker

Designed to continuously cook the mussel, cockles or other mollusks. Fully automated.

Productio: Based on client´s needs (maximum 3000 kgs/hour).

Dimensions: Customized to the required production.

Made of stainless steel AISI 316 and other stainless steels with high-performance oxidation resistance.

Do you need more info?

Call us on the phone +34 986 44 29 04

Write to us at info@gaictech.com

Features

- Pneumatic door system.

- Pneumatic door loading/unloading system for mussels.

- Reception hopper for storage of products.

- Stainless steel indoor conveyor with high-performance oxidation resistance. Conveyor belt made of the same material.

- Cyclone mounted on the side to channel the steam discharges out of the factory.

- Fully automated cycles with option to re-program.

- PLC industrial control for the whole system.

- Option to remote support by accessing a PC via Ethernet.

DO YOU NEED MORE INFO?

If you need more information or have any questions, do not hesitate to contact us.

ANOTHER MOLLUSC LINES

Mussel Dehydrator

Mussel Cooker

Mussel Declumper and Trommel Washer

In-Shell Mussel Grader

Debysser-Mussel Debyssing (Debearding) Machine

Shell and Mussel Separator by Vibration and Laminar Flow

Mussel Meat Grader by Vibration

Automatic Volumetric Filling Machine For Shellfish

Glazing and Box Filling System

Brusher For Mussels