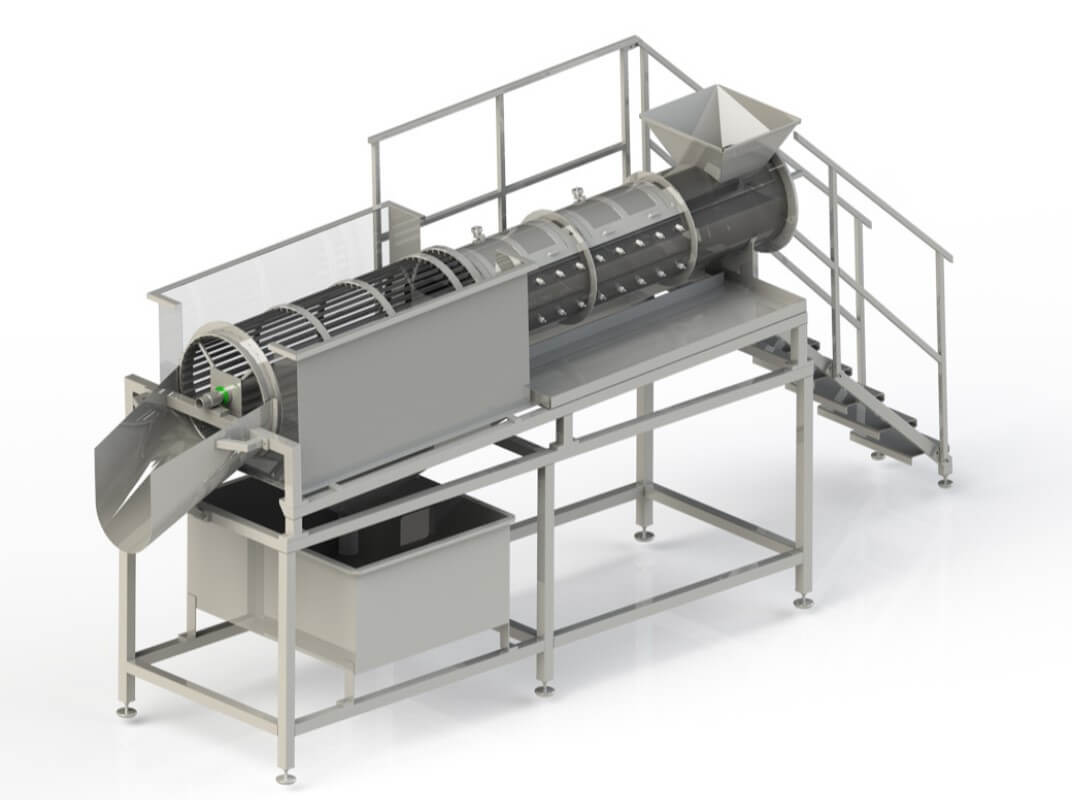

Mussel Declumper and Trommel Washer

Designed to decluster the mussel cones coming from farming and their subsequent washed.

Production: Based on client´s needs (maximum 5000 kgs/hour).

Dimensions: Customized to the required production.

Made of stainless steel AISI 316.

Do you need more info?

Call us on the phone +34 986 44 29 04

Write to us at info@gaictech.com

Features

- Rotary movement through special designed blades for declustering.

- Mussel washing after declustering, in rotary drum.

- Detection and rejection of sea waste, unmarketable size or broken shells in the washing trum.

- Water collection trays.

DO YOU NEED MORE INFO?

If you need more information or have any questions, do not hesitate to contact us.

ANOTHER MOLLUSC LINES

Mussel Dehydrator

Mussel Cooker

Mussel Declumper and Trommel Washer

In-Shell Mussel Grader

Debysser-Mussel Debyssing (Debearding) Machine

Shell and Mussel Separator by Vibration and Laminar Flow

Mussel Meat Grader by Vibration

Automatic Volumetric Filling Machine For Shellfish

Glazing and Box Filling System

Brusher For Mussels