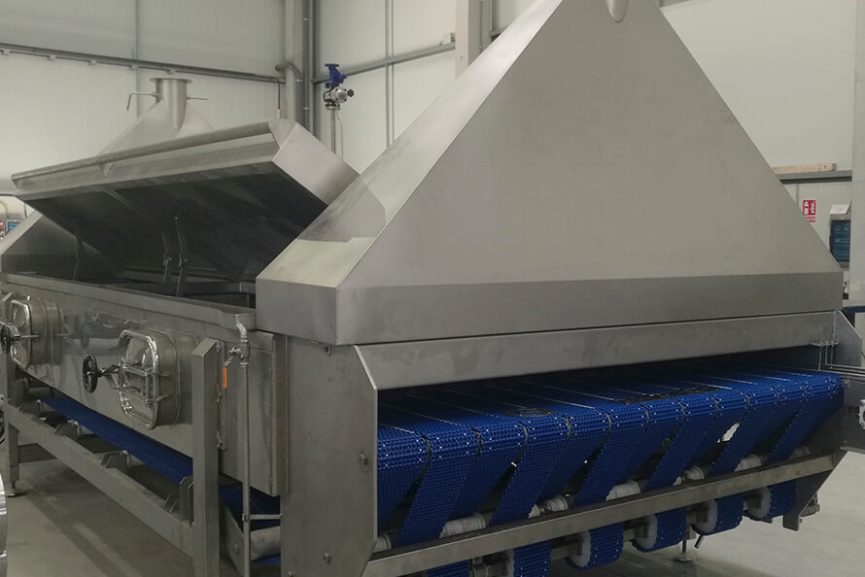

PASTEURISERS

Designed for the continuous pasteurisation of a wide variety of products of animal or vegetable origin, packaged in any type of format.

- Production: According to the client’s needs.

- AISI 304 stainless steel construction.

Do you need more info?

Call us on the phone +34 986 44 29 04

Write to us at info@gaictech.com

FEATURES

- Especially indicated in production lines where it is not possible to carry out discontinuous pasteursation in traditional autoclaves or when there are no space limitations.

- Automatic process control.

- Optimal steam consumption.

- Direct steam pasteurization..

Do you need more info?

If you need more information or have any questions, do not hesitate to contact us..

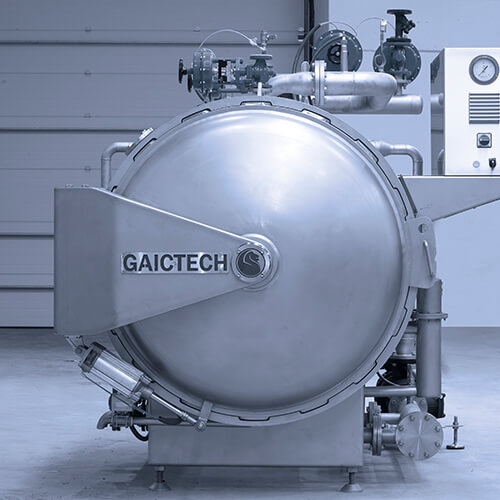

OTHER AUTOCLAVE PRODUCTS